Rigorous Test Facility

Depending on customers needs, we do the following tests in our Rig Machine to ensure our quality:

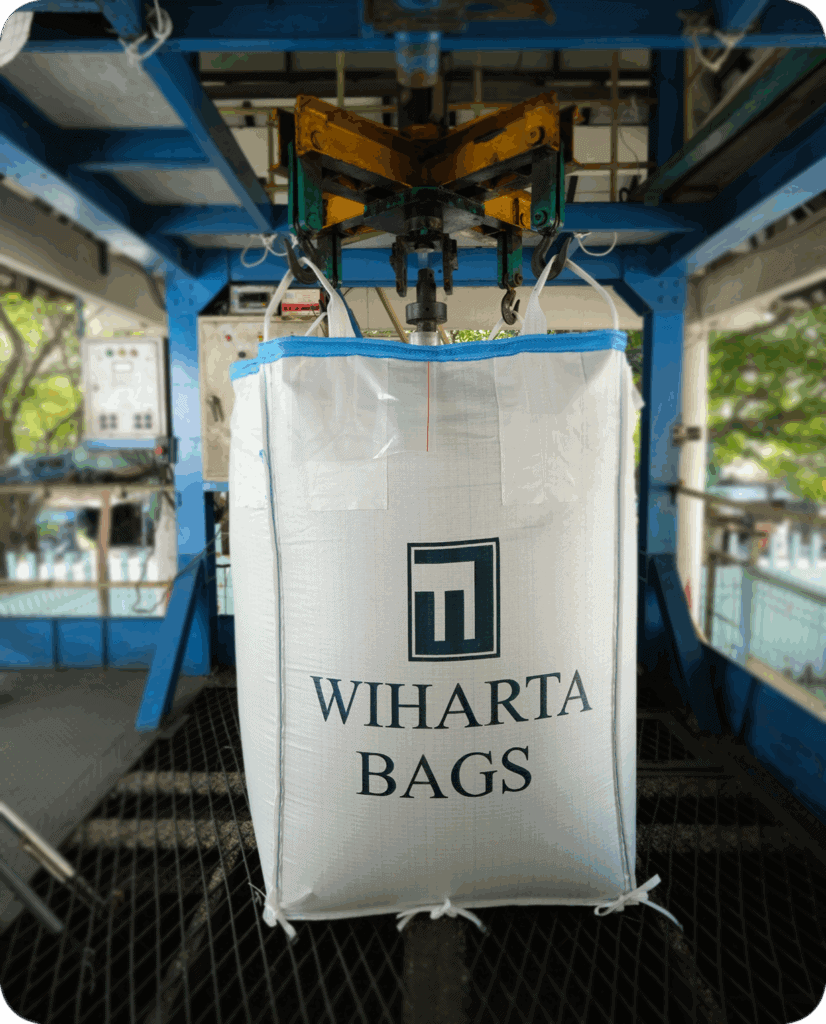

Cyclic Test

The filled bag is hanged from its loops and it must maintain a total load of 2 times of SWL depending on the customer requirements for 5 minutes.

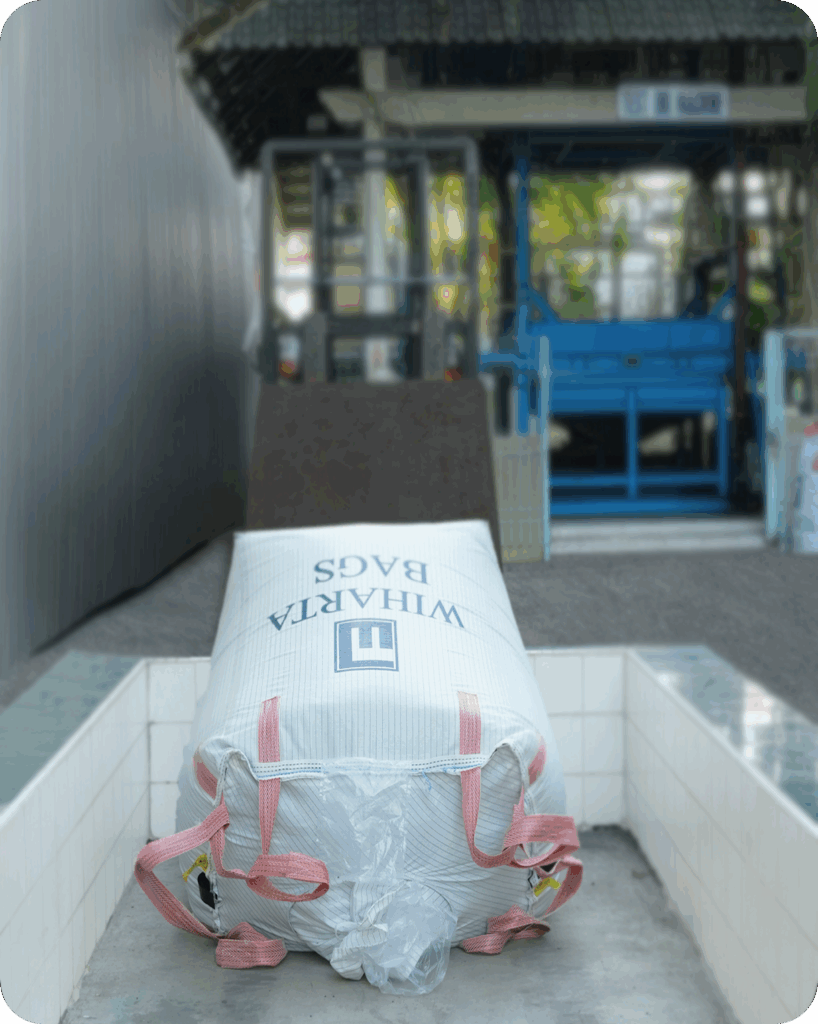

Drop Test

The filled bag is dropped from a specific height and the bag did not break or burst during the trial.

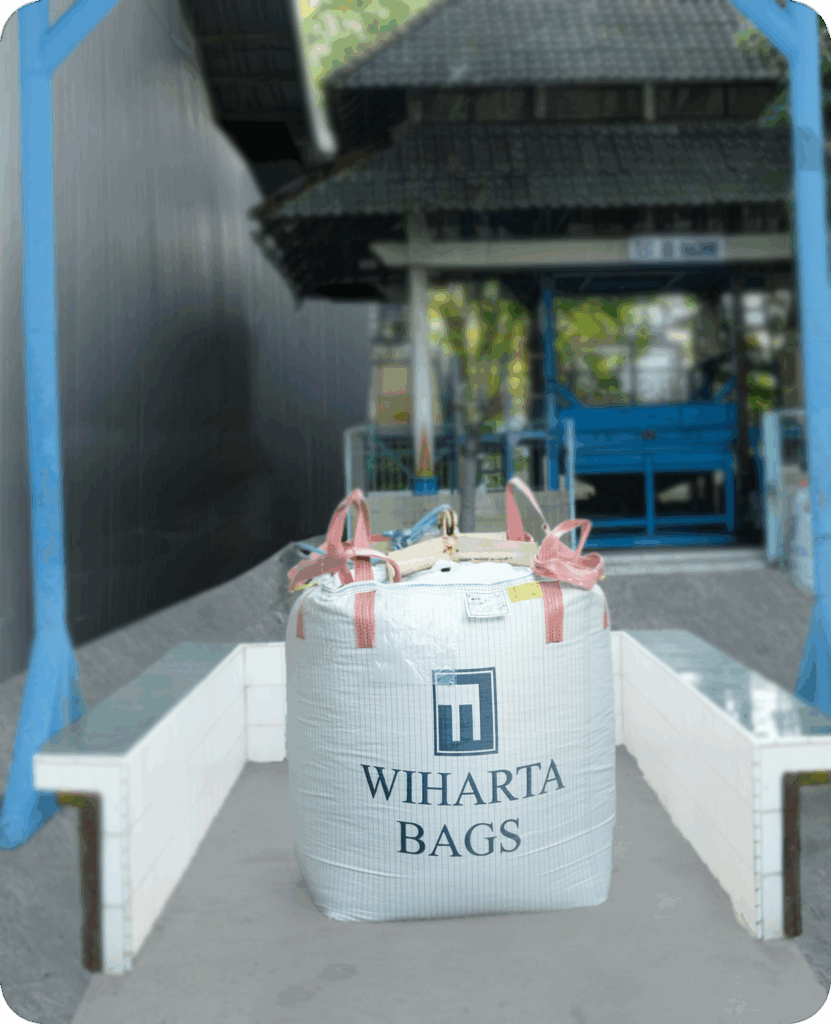

Topple Test

The filled bag is placed on a raised platform and forced to topple over from a specific height and the bag did not break or burst during the trial.

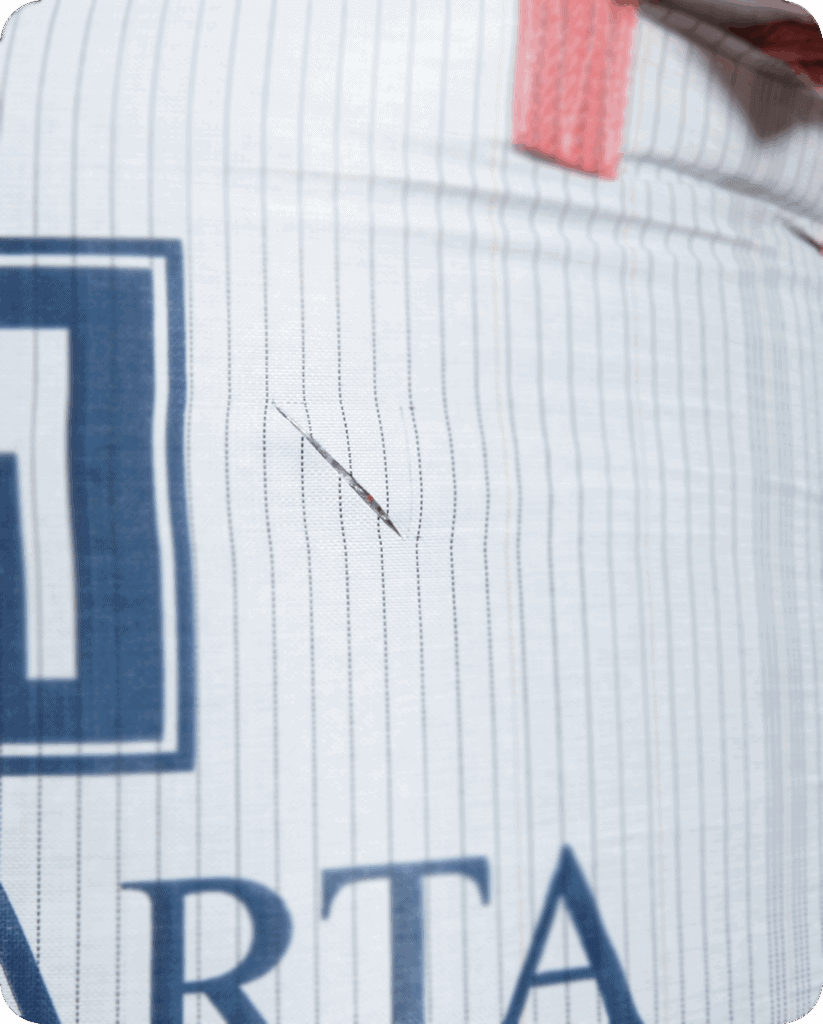

Righting Test

The filled bag is knocked onto its side and put upright again using only 2 lift loops. The bag and the loops should not show any sign of damage after the test.

1 and 2 Loop Test

Bags featuring a 1- or 2-Loop FIBC configuration are rigorously tested to ensure that the design is capable of withstanding real-world stresses and usage conditions.