Rigorus Test Facility

We recognize that every company must adhere to specific packaging standards. These include industry-specific requirements, which ensure the packaging is suited to the nature of the goods inside, as well as company-specific requirements, such as environmental conditions, handling equipment, and operational needs.

To meet these diverse requirements, we operate an in-house laboratory where we rigorously test the quality of our materials, assess the Safe Working Load (SWL) and Safety Factor (SF) for each FIBC, and ensure every bag meets the highest standards of durability and reliability.

Additionally, each FIBC bag is assigned a unique traceability code, allowing us to monitor its production history. In the event of any concerns, this system enables us to conduct a thorough analysis, identify root causes, and ensure continuous quality improvement.

Depending on customers needs, we do the following tests in our Rig Machine to ensure our quality:

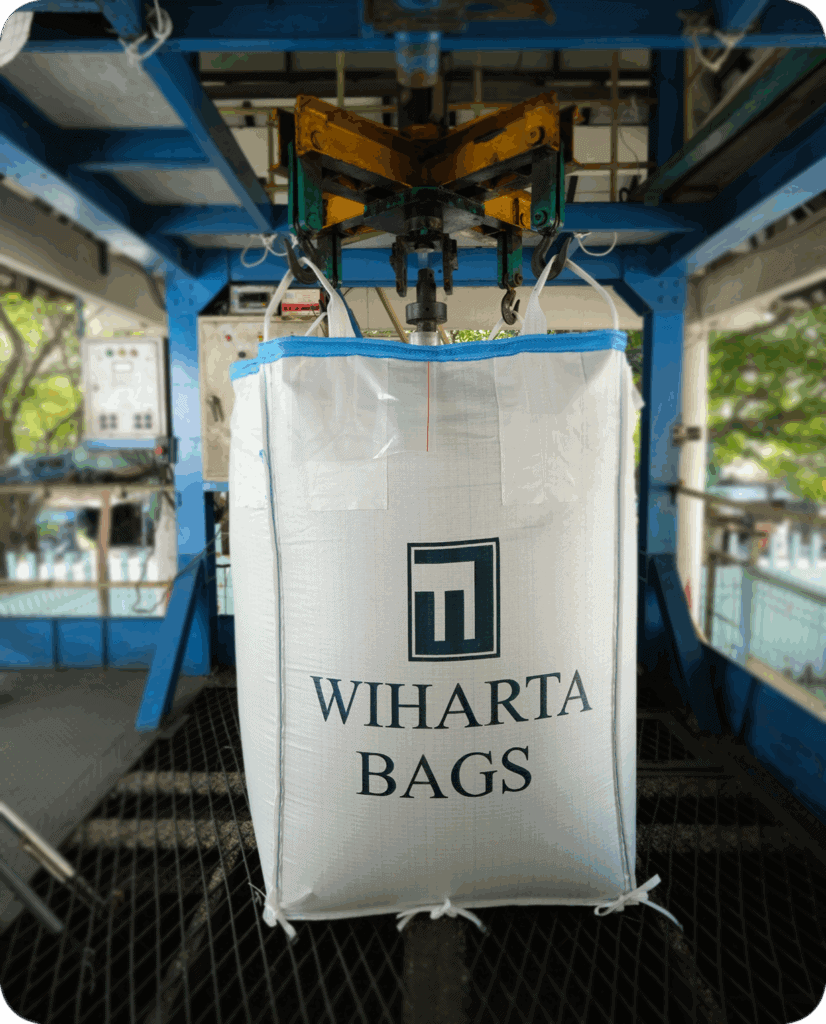

Cyclic Test

The filled bag is hanged from its loops and it must maintain a total load of 2 times of SWL depending on the customer requirements for 5 minutes.

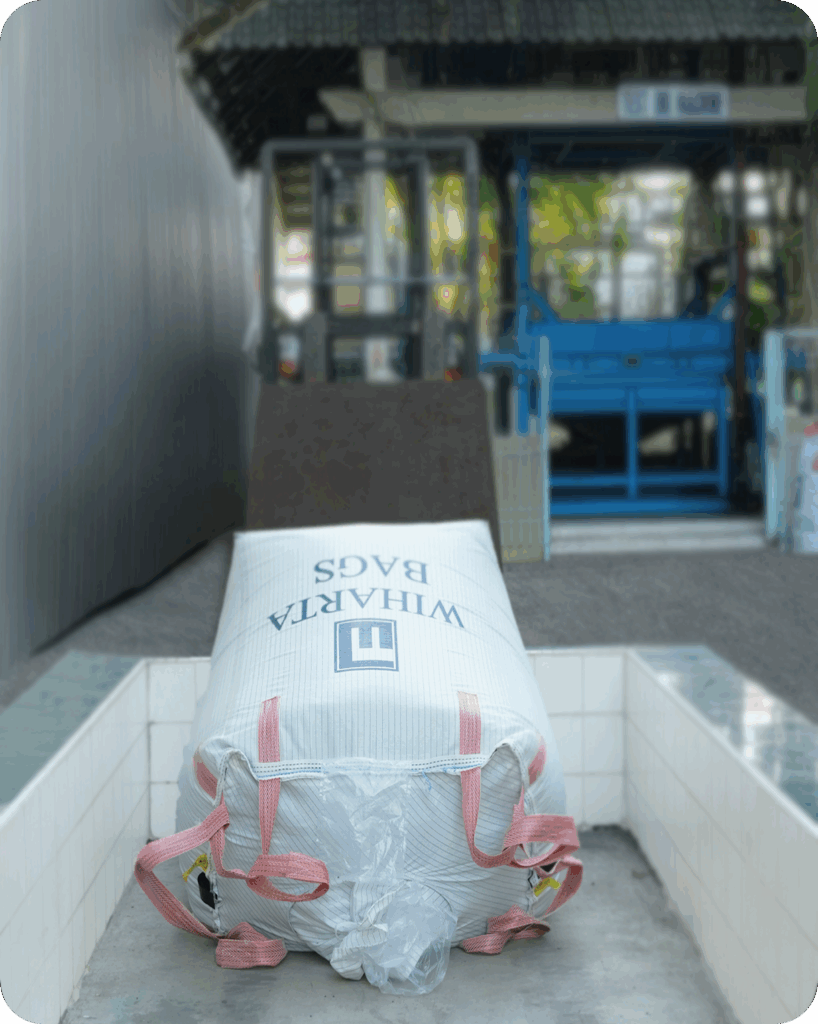

Drop Test

The filled bag is dropped from a specific height and the bag did not break or burst during the trial.

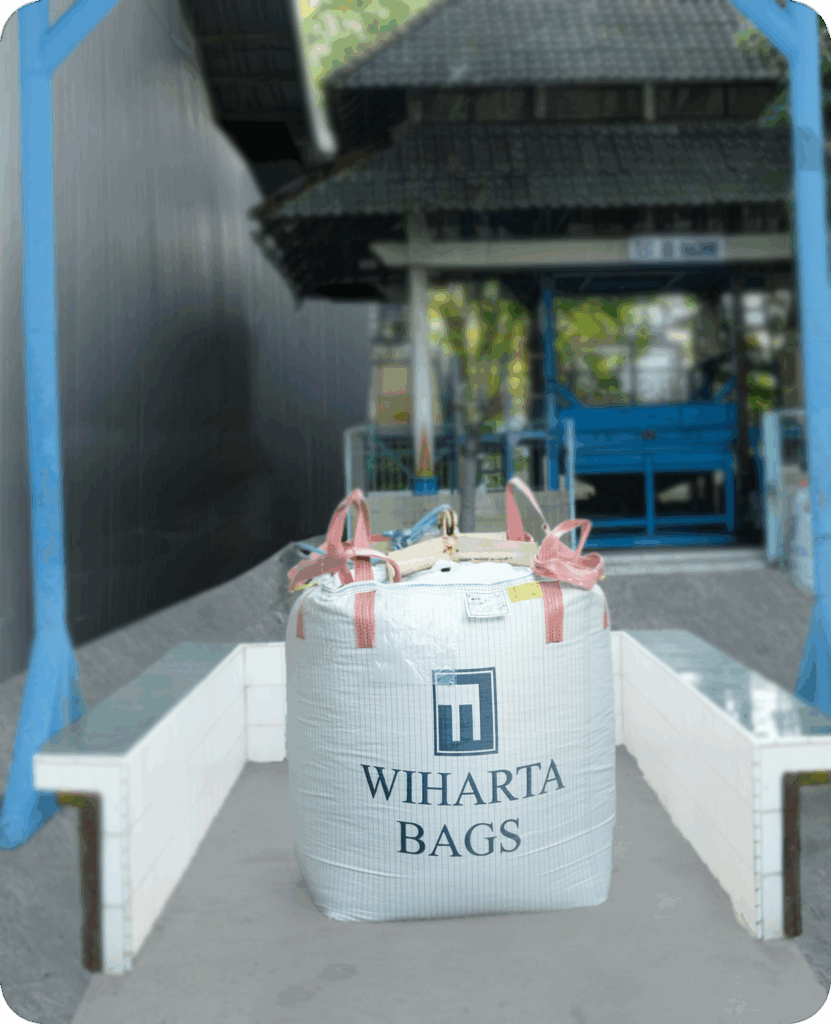

Topple Test

The filled bag is placed on a raised platform and forced to topple over from a specific height and the bag did not break or burst during the trial.

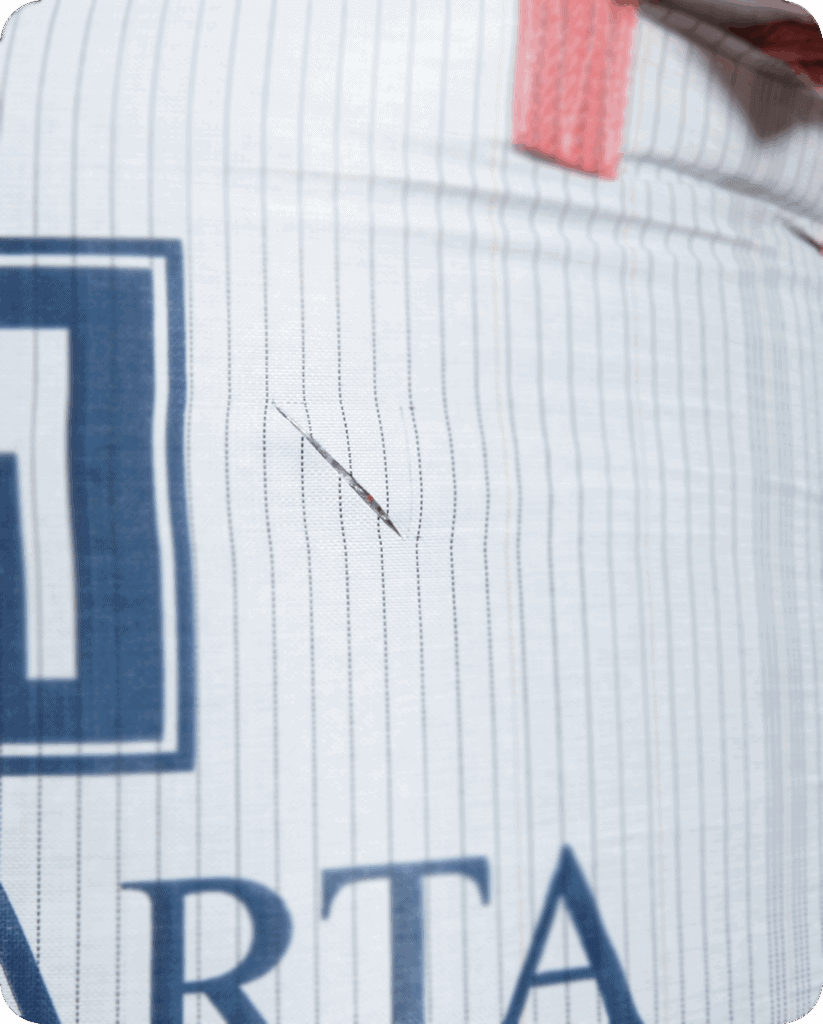

Righting Test

The filled bag is knocked onto its side and put upright again using only 2 lift loops. The bag and the loops should not show any sign of damage after the test.

1 and 2 Loop Test

Bags featuring a 1- or 2-Loop FIBC configuration are rigorously tested to ensure that the design is capable of withstanding real-world stresses and usage conditions.