Types of FIBCs

“Our FIBC bags, marketed under the Wicon® brand, are designed to meet a wide range of industrial needs and are available in four distinct types: Type A, B, C, and D. Each type is classified based on its electrostatic properties and grounding requirements, ensuring safe and efficient handling for various applications.”

Type A FIBC or Bulk bags

Made from plain-woven polypropylene and other non-conductive fabrics, there is no static protection provided by Type A FIBCs.

Product Description

Type A jumbo bags are produced from a non-conductive fabric

without any protective features against static electricity accumulation. Common uses of types A include transport and store non-flammable and non-explosive products.

Some industries that use this type include: agriculture, food, pharmaceuticals, construction, chemical, mining, and textiles. It is crucial to make sure that no flammable solvent or gases surround the bag.

Product Specification

| Material | Polypropylene |

| Construction | U-Panel, Circular, 4 Panel, or Baffle |

| Safety factor | 3:1, 5:1, 6:1 |

| Safety Working Load | 500 Kgs to 2,000 Kgs |

| Fabric | Laminated / Unlaminated, Inner Liner |

| Printing | Logos, color customization |

Type B FIBC or Bulk bags

Made from plain-woven polypropylene fabrics or other non-conductive material but have a low breakdown voltage material to prevent an incident where highly energetic, and dangerous propagating brush discharges occur.

Product Description

Type B jumbo bags are produced from non-conductive fabric with a low breakdown voltage material. This provides safety in preventing less than 6kV propagating brush discharges. These bags can be used to transport and store dry, non-flammable products provided no flammable gases and vapours surround the bag and no conductive materials such as water and oil on the bag surface.

Some industries that use this bag include: chemical, pharmaceuticals, paints, agriculture, mining, and food.

Product Specification

| Material | Polypropylene |

| Construction | U-Panel, Circular, 4 Panel, or Baffle |

| Safety factor | 3:1, 5:1, 6:1 |

| Safety Working Load | 500 Kgs to 2,000 Kgs |

| Fabric | Laminated / Unlaminated, Inner Liner |

| Printing | Logos, color customization |

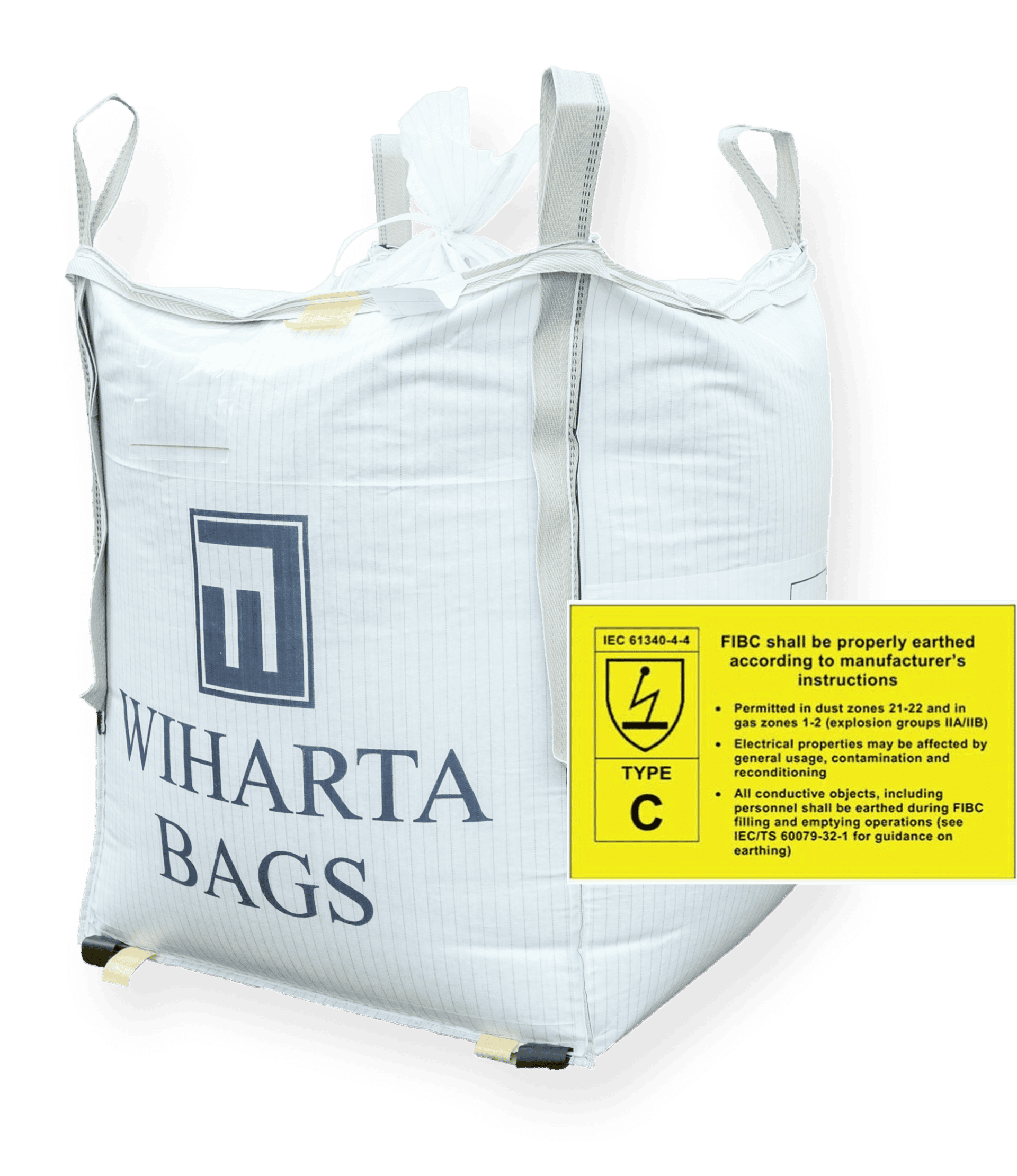

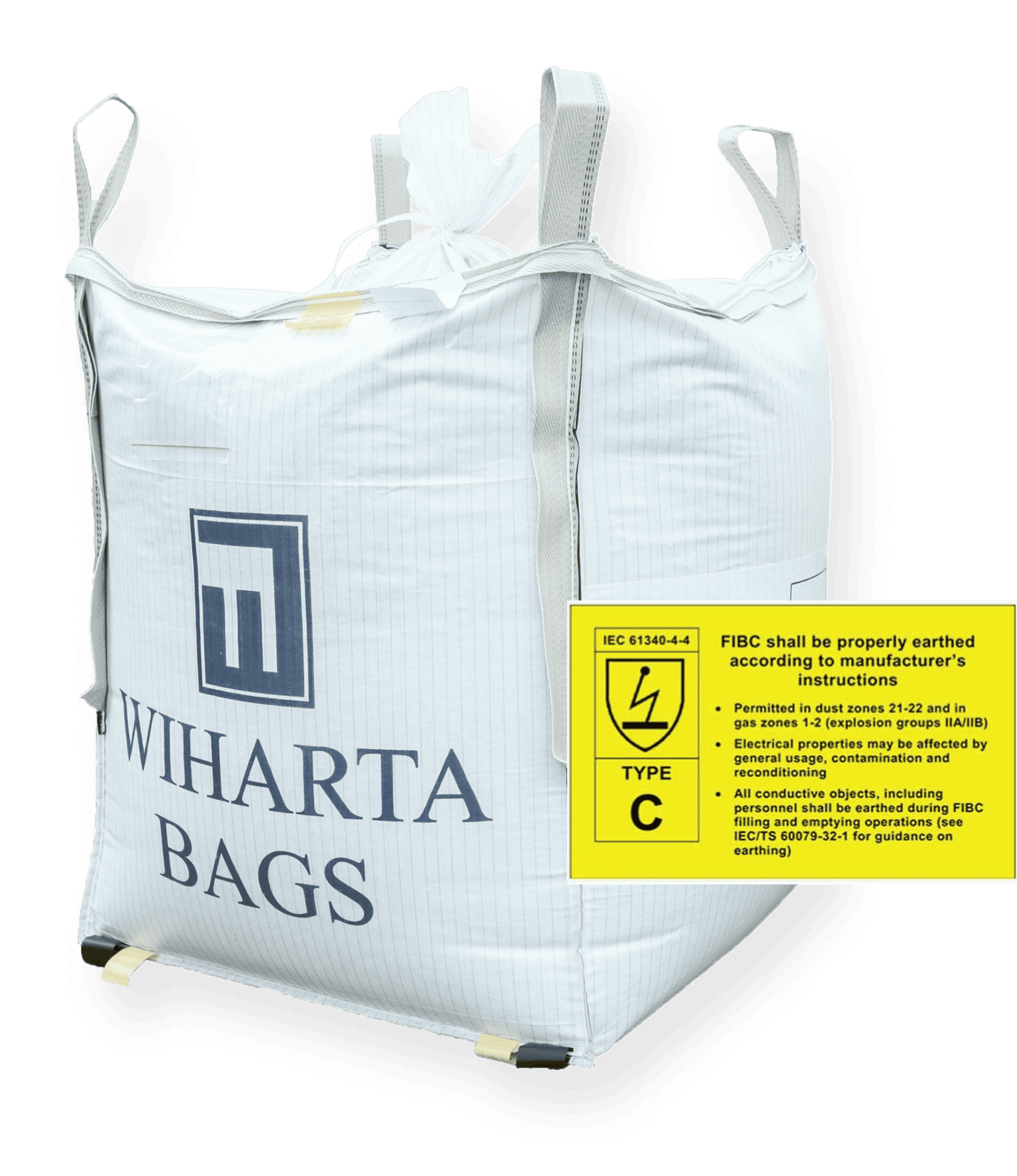

Type C FIBC or Bulk bags

Made from conductive fabric and come with conductive threads or tapes sewn into the fabric. These big bags are only electrically conductive when grounded, and extra measures are required during filling and unloading to prevent powerful sparks discharges.

Product Description

Type C bags are also known as Conductive FIBCs and are produced from fabrics with conductive fibres or tapes. Conductive FIBCs can be used to transport and store flammable powder products and are safe to use even when flammable gases and vapours are present in the environment, as long as the bag is grounded during filling and unloading the products. The voltage rating of the conductive fibres on the bag must be in contact with less than 107-6 ohms of resistance to the ground.

Some industries that use this bag include: chemical, pharmaceuticals, food, agriculture, plastic, timbre, and mining. It is crucial to ensure that the ground connection available and not damaged prior to filling or unloading process to prevent powerful spark discharges.

Product Specification

| Material | Polypropylene |

| Construction | U-Panel, Circular, 4 Panel, or Baffle |

| Safety factor | 3:1, 5:1, 6:1 |

| Safety Working Load | 500 Kgs to 2,000 Kgs |

| Fabric | Laminated / Unlaminated, Inner Liner |

| Printing | Logos, color customization |

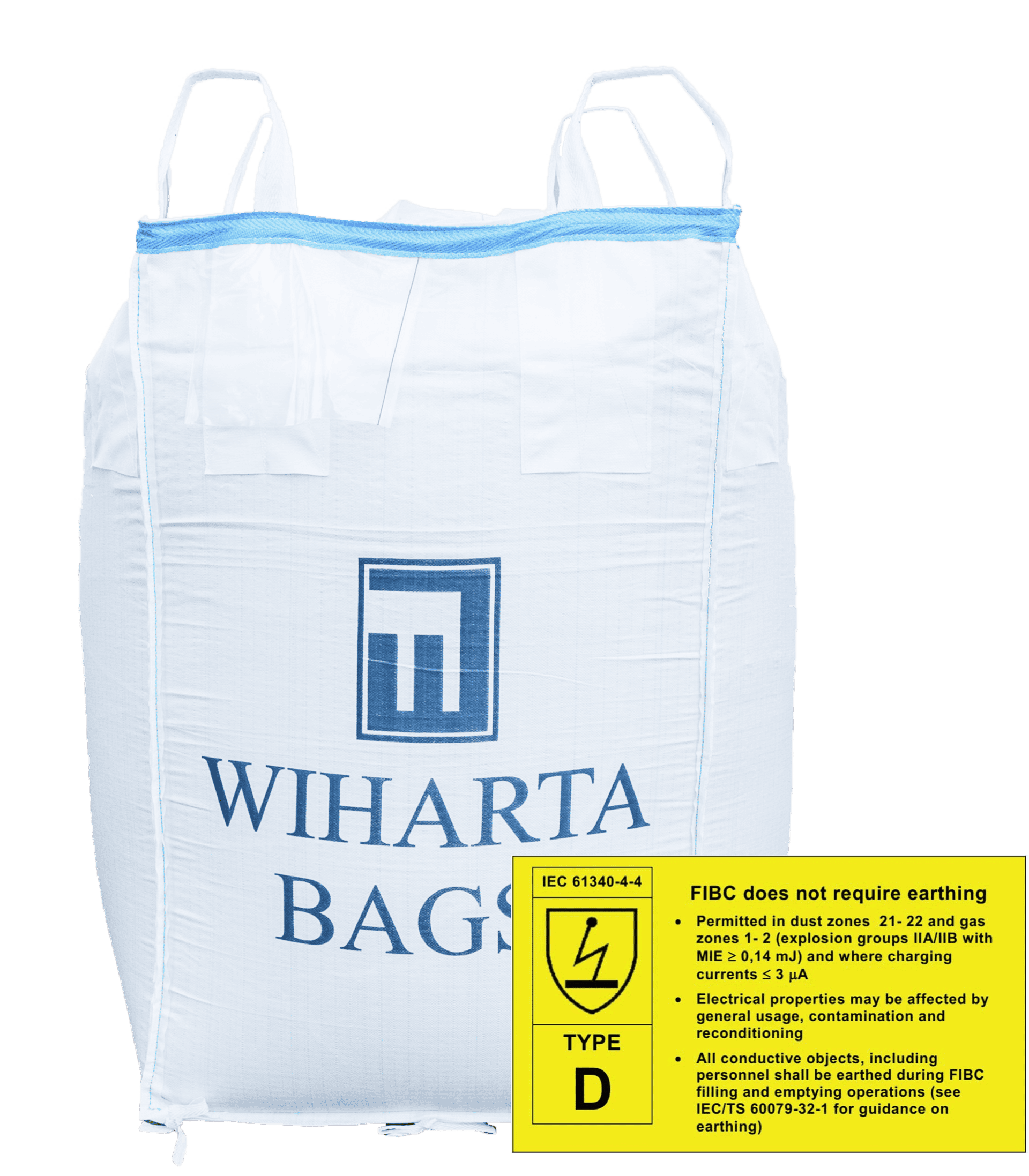

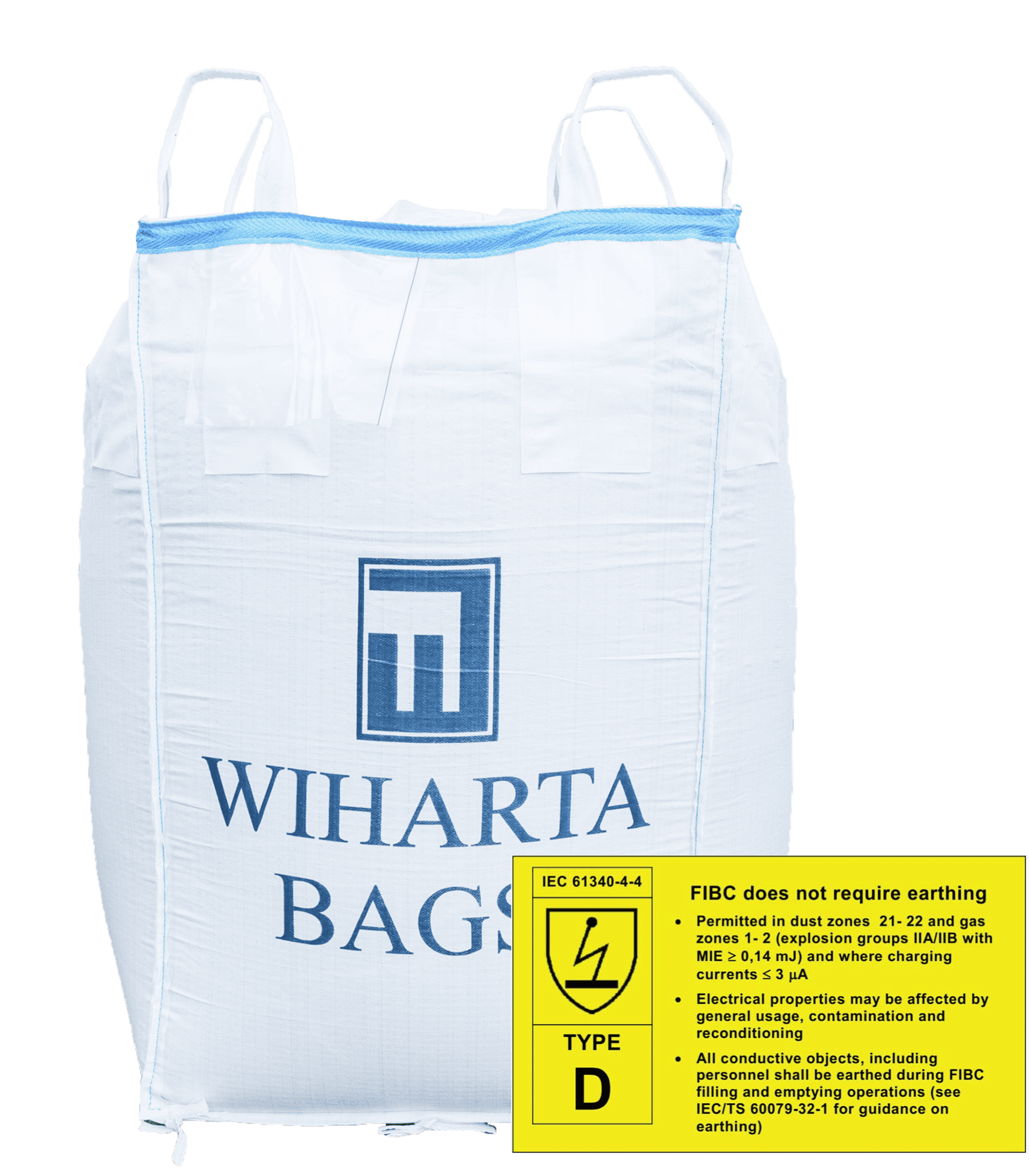

Type D FIBC or Bulk bags

Type D bags are made from antistatic and static dissipative fabrics, manufactured with fabric containing quasi-conductive yarns. Type D anti-static FIBC bulk containers are resistant to brush discharges and sparks. The key advantage of these bags is that they don’t need to be grounded during filling and unloading. This can considerably speed up workflows and ensure personnel safety.

Product Description

Type D bags are made from antistatic and static dissipative fabrics, manufactured with fabric containing quasi-conductive yarns. Type D anti-static FIBC bulk containers are resistant to brush discharges and sparks. The key advantage of these bags is that they don’t need to be grounded during filling and unloading. This can considerably speed up workflows and ensure personnel safety.

This type of bag can be used to transport flammable powder products in environments where solvents and combustible gases are present.

Product Specification

| Material | Polypropylene |

| Construction | U-Panel, Circular, 4 Panel, or Baffle |

| Safety factor | 3:1, 5:1, 6:1 |

| Safety Working Load | 500 Kgs to 2,000 Kgs |

| Fabric | Laminated / Unlaminated, Inner Liner |

| Printing | Logos, color customization |